Customization Support

As a leading manufacturer of Door Handles, Door Hinges, Door Locks, and Door Stoppers, shower door lock professional manufacturers, we understand the importance of catering to unique customer requirements. Our products are designed to support customization, allowing you to choose from a wide range of finishes, styles, and sizes. Whether you need a specific design or want to match your existing hardware, our dedicated team will work closely with you to create tailor-made solutions that meet your exact specifications.

ISO9001:2015 Certification

At our production facility, quality is paramount. We are proud to have achieved ISO9001:2015 certification, which ensures that our manufacturing processes adhere to the highest international standards. This certification signifies our commitment to delivering superior products that consistently meet or exceed customer expectations. When you choose our products, you can trust in their durability, reliability, and overall quality.

Manufacturer Direct

By choosing our products, you benefit from direct sourcing from the manufacturer. As a trusted manufacturer of Piano Hinges, Shower Hinges, adhesive bathroom hooks professional manufacturers, Cabinet Handles, long grab bars factory in china, grab bars producer, House Numbers, shower screen pivot hinge bunnings, and Bathroom Hooks, we have complete control over the production process, from design to manufacturing. This enables us to offer competitive pricing without compromising on quality. With no middlemen involved, you can be assured of receiving the best value for your investment.

Comprehensive One-Stop Service

We take pride in providing a comprehensive one-stop service to our customers. From initial concept development to final product delivery, we are with you every step of the way. Our dedicated team of professionals will assist you in selecting the right products, guiding you through the customization process, providing technical expertise, and ensuring timely delivery. With our commitment to customer satisfaction, you can expect a seamless and hassle-free experience when working with us.

Related Products

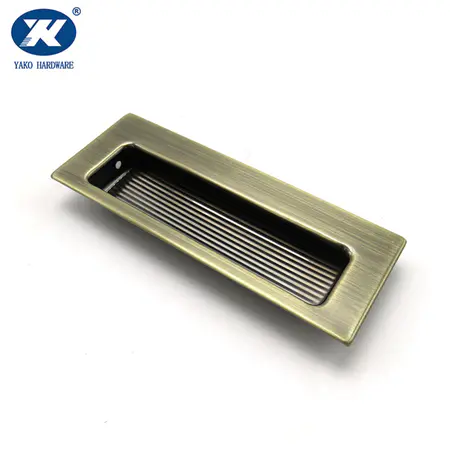

More items about door handle

【Good price Handle 】YAKO hardware Internal Stainless Steel Tube Lever Type Handle with plastic base

Yake Hardware Products Co., Ltd. is a professional manufacturer of high-end architectural hardware products. In the past 20 years, it has mainly produced doors, windows, glass, kitchen utensils, and outdoor products.

Covering an area of 6,000 square meters, with 5 production lines and nearly 100 employees, Yako can provide more than 2,000 solutions for architectural projects and interior design.

Adhering to the tenet of "quality first, customer first", we have always been committed to providing every customer with excellent quality and enthusiastic service at the most competitive price.

Smart Integration: Convenience at Your Fingertips

Modern advancements have allowed for the integration of smart technology into door handles. Smart door handles can be connected to home automation systems, allowing for keyless entry, remote access control, and personalized settings. This seamless integration of technology adds convenience and enhances the overall functionality of door handles.

What is the principle of the door handle?

The principle of the door handle is the principle of lever, the fixed point on the wall is the fulcrum, the action point of the handle force. Leverage has three points: the force point, the fulcrum point and the resistance point.

When the distance from the force point to the fulcrum is greater than the distance from the resistance point to the fulcrum, it saves effort; when the distance from the force point to the fulcrum is equal to the distance from the resistance point to the fulcrum, it saves effort and effort; when the distance from the force point to the fulcrum is less than the distance from the resistance point to the fulcrum laborious.

The handle can be used to hold, manipulate or move mechanical equipment and cabinet equipment (mostly on the door), and it is convenient for door opening, handle, handrail and other metal handles. The lever principle is widely used in life, bringing people's life. More effort and convenience.

Door handles are classified by material

Although doors also come in a variety of materials, compared with door handles, the variety is still much less. The reason why the price of anti-theft door handles is different is largely due to the difference in materials. Ceramic, solid wood, and metal door handles sold the most. In addition to these, there are glass materials, crystal, plastic, alloy materials and so on. When choosing a door handle, you don't have to choose the same door handle as the door material.

Door handle style

The door handle can be customized in different shapes, the conventional one is a tubular door handle, and the tubular shape is divided into round tube and square tube. In addition to the tubular shape, the door handle also has many special-shaped styles, which can be divided into precision casting door handles and stamping imitation precision casting door handles according to the process.

User Reviews

What users say about YAKO

Frequently Asked Question

Do you have any question?

Regular tubular handles start at 50 sets, and special-shaped models start at 500-1000.

Provide detailed drawings or templates can be customized.

There are 200,000 normal usage times.

Door handles are made from a variety of materials, including stainless steel, brass, aluminum, and even wood. These materials offer different styles, durability, and finishes to suit various design preferences.

Yes, there are various types of door handles, including lever handles, knob handles, and pull handles. Each type offers a unique look and functionality, allowing for customization based on individual needs and design preferences.