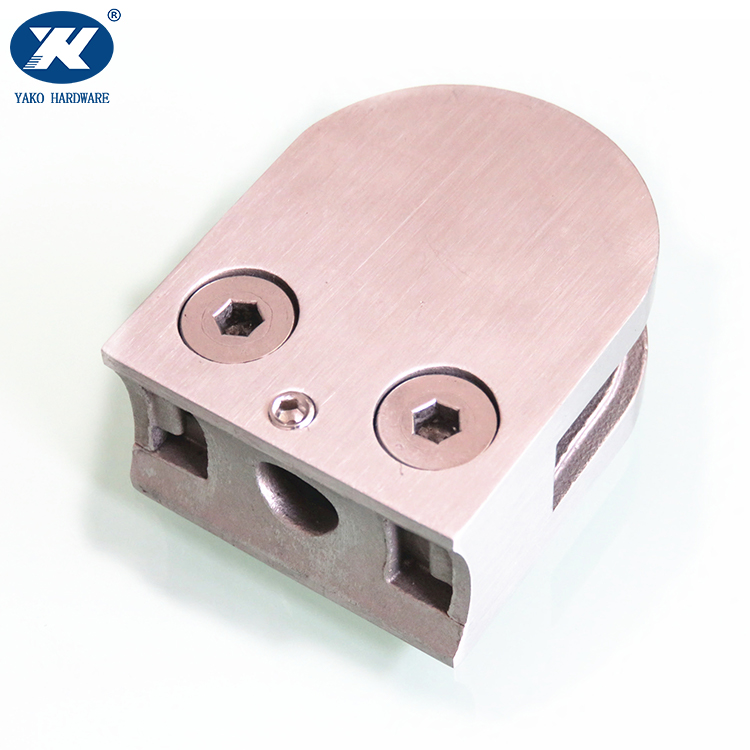

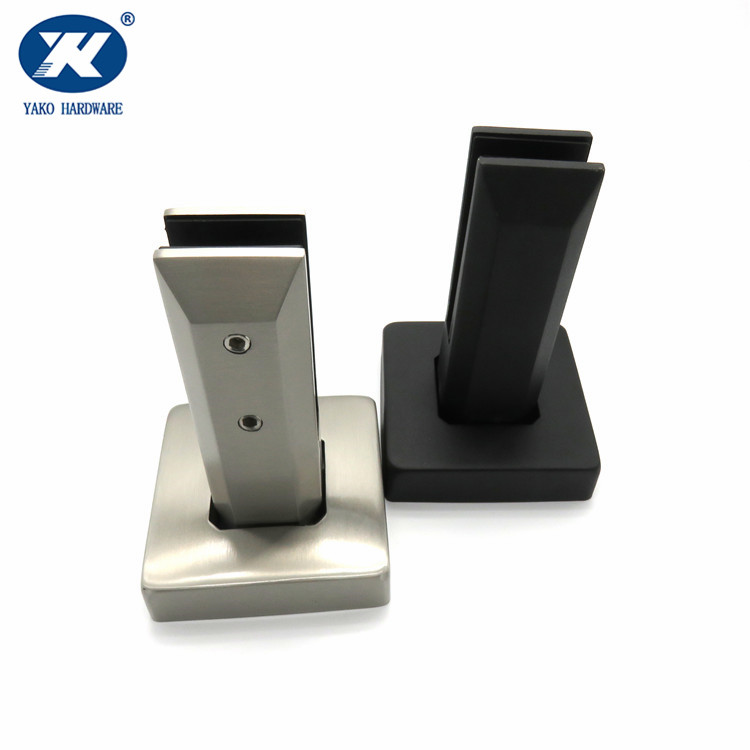

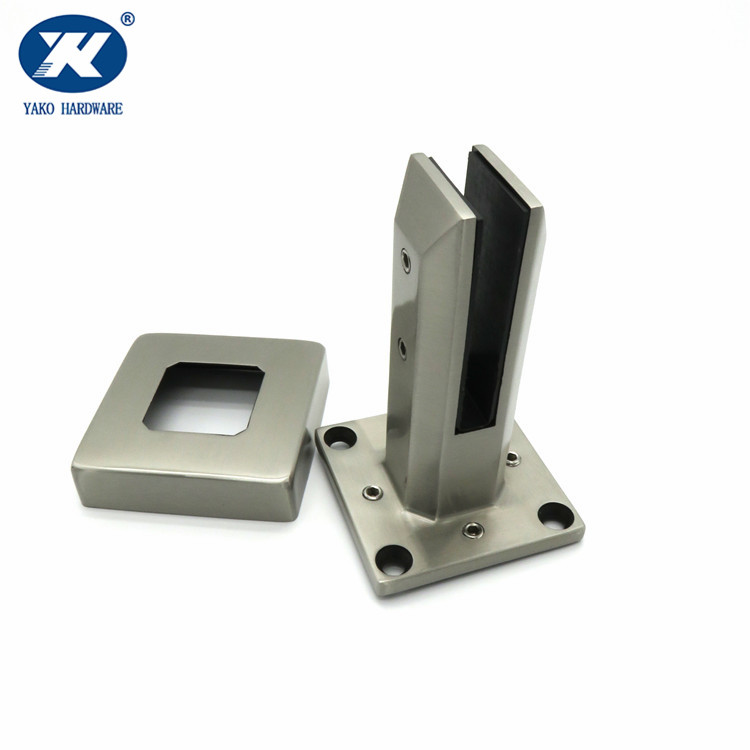

Railing Glass Spigot

- Product Information

Whether you are installing glass panels in a shower enclosure, glass railing system or display case, these Railing Glass Spigot provide the strength and durability needed to ensure a safe and stable installation.

A Railing Glass Spigot is a hardware accessory used to secure and support glass, widely used in the construction and decoration industries. Its primary function is to securely attach glass panels to frames or other structures, ensuring the stability and safety of the glass. Typically made of high-strength stainless steel, it offers excellent corrosion and oxidation resistance, making it suitable for use in a variety of environments. With the dual pursuit of aesthetics and functionality in modern architectural design, stainless steel glass clamps have become an indispensable element. They not only enhance the overall aesthetic of a building but also provide designers with greater creative freedom. Whether in commercial buildings, residential projects, or public facilities, stainless steel glass clamps play a vital role, becoming a key component in connecting disparate materials.

Railing Glass Spigot Specifications:

| Item | Parameter |

| Model Number | YGS-152 |

| Material | Stainless Steel/Aluminium Alloy/Brass/Zinc Alloy |

| Finish | SSS/PSS/PVD/SN/CP/AB/ACM/PB/SB/customized |

Warranty | 1Year |

| After-sale Service | Online technical support,Onsite Training Onsite Inspection |

| Project Solution Capability | Graphic Design |

| Application | Hotel,Villa,Apartment,Hospital |

| Design Style | Modern |

| Place of Origin | Guangdong China |

| Brand Name | YAKO |

| MOQ | 100 SETS /size/finish |

| Package | One Set in one plastic bag |

| Delivery time | Usually 25-35 days |

| Sample | Accept |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

Features of Railing Glass Spigot

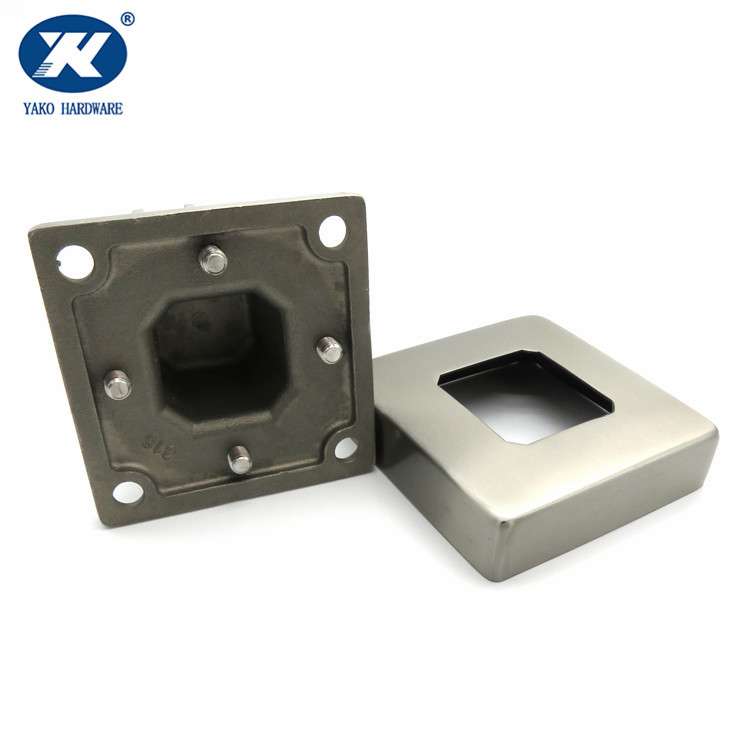

High-quality materials

Stainless steel glass holders are made of high-quality stainless steel, ensuring durability in a variety of environments. According to industry standards, 304 and 316 stainless steel are the most commonly used materials, offering excellent corrosion resistance and suitability for outdoor and humid environments. A variety of surface treatments, such as SSS and PSS, further enhance their wear resistance and aesthetics.

Diverse surface treatment

This product offers a variety of surface finishes, including PVD, SN, and CP, to meet diverse customer needs. Each treatment effectively enhances the appearance and durability of the stainless steel glass bracket, ensuring it maintains its gloss and aesthetics over long-term use. According to industry standards, the thickness and uniformity of the surface treatment directly impacts the product’s lifespan.

Customizable design

Stainless steel glass supports are customizable, allowing customers to select the size, color, and finish to suit their specific needs. This customization allows the product to better integrate into various architectural styles and meet individual design requirements. Customization services within the industry typically adhere to strict production standards to ensure product quality.

Strong load-bearing capacity

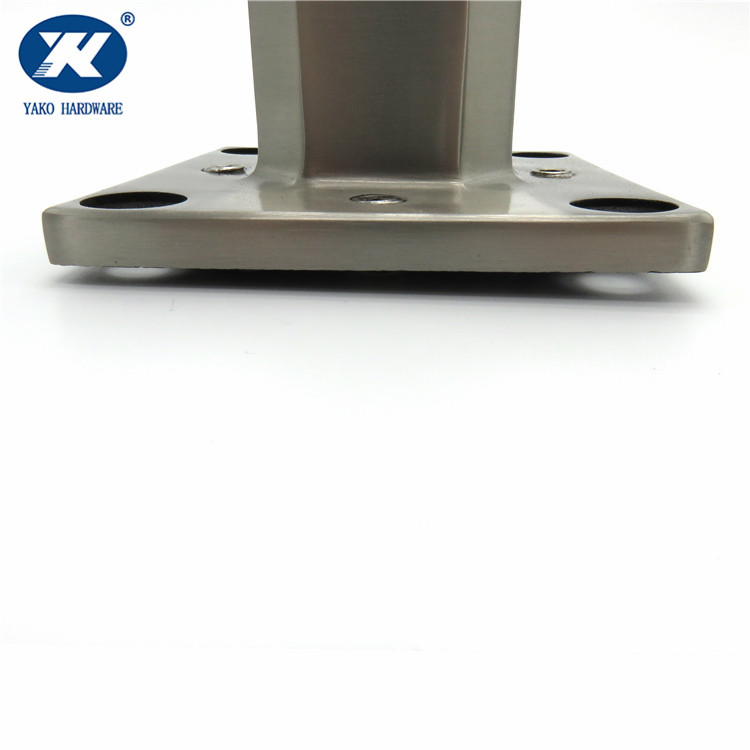

Designed with load-bearing capacity in mind, this product can safely support glass with a thickness of 10mm to 20mm. According to relevant standards, the bracket’s load-bearing capacity is rigorously tested to ensure safety and stability under high loads. This feature makes stainless steel glass brackets widely used in high-rise buildings and large commercial spaces.

Easy Installation

The stainless steel glass supports are designed with ease of installation in mind and come with standardized mounting accessories, ensuring quick and easy installation. Every step of the installation process has been optimized according to industry standards to reduce construction time and costs and improve work efficiency.

Weather resistance

Stainless steel glass supports have excellent weather resistance and can resist erosion by ultraviolet rays, rain, and other environmental factors. According to relevant testing standards, this product can still maintain its performance and appearance under extreme climate conditions and is suitable for use in buildings under various climate conditions.

Application of Railing Glass Spigot

Commercial buildings

Railing Glass Spigots are widely used in glass curtain walls and partition systems in commercial buildings. Their elegant appearance and strong load-bearing capacity enable architects to design modern commercial spaces. By using Railing Glass Spigots, the overall visual impact of a building is enhanced, attracting more customers and visitors.

Residential projects

In modern residential design, Railing Glass Spigots are used for glass railings in balconies, stairways, and bathrooms. Their safety and aesthetics make homes more comfortable and stylish. Using Railing Glass Spigots allows homeowners to enjoy expansive views while ensuring the safety of their family members.

Hotels and Resorts

Hotels and resorts often strive for luxury and comfort, making Railing Glass Spigots particularly important in these settings. They are used in pool enclosures, sunrooms, and recreational areas, enhancing the overall design. The use of Railing Glass Spigots makes these spaces both safe and visually appealing.

Public facilities

In public facilities such as airports, train stations, and shopping malls, Railing Glass Spigots are widely used for glass partitions in pedestrian walkways and waiting areas. Their durability and safety ensure the safety of crowded areas, and the design of Railing Glass Spigots also adds a modern touch to public spaces.

Trade Shows

Railing Glass Spigots are used in display cases and booths at trade shows and exhibitions. Their transparent nature allows exhibits to be fully displayed while maintaining a clean and aesthetically pleasing appearance. Using Railing Glass Spigots, exhibit designers can create eye-catching displays that attract a wider audience.

Maintenance of Railing Glass Spigot

Regular cleaning

Maintenance of stainless steel glass stands begins with regular cleaning. Use a mild detergent and a soft cloth, avoiding abrasive cleaning tools that can scratch the surface. When cleaning, be careful to remove dirt and scale to maintain its gloss and aesthetic appeal. Regular cleaning not only extends the life of the product but also preserves its appearance.

Check the fasteners

Regularly check the fasteners of the stainless steel glass bracket to ensure their firmness. Fasteners may loosen over time due to environmental factors. Regular inspection and tightening can prevent potential safety hazards and ensure the stability and safety of the bracket during use.

Prevent corrosion

Although stainless steel has good corrosion resistance, it still requires careful protection in certain extreme environments. Avoid prolonged contact with salt water or chemicals, and rinse with clean water regularly to remove possible sources of corrosion. Keeping the bracket dry and clean will help extend its service life.

Avoid impact with heavy objects

Avoid heavy impact or severe vibration when using stainless steel glass supports. Although the product is designed to have a strong load-bearing capacity, excessive impact may cause damage. Keeping the surrounding environment clean and avoiding unnecessary collisions will help protect the integrity of the support.

Regular professional inspection

It’s recommended to have your stainless steel glass stand inspected and maintained regularly by a professional. Professionals can identify potential issues and provide solutions, ensuring the safety and stability of your product during use. Regular professional maintenance not only extends the life of your product but also ensures it remains in optimal condition.